Information regarding the fire incident that occurred in a toilet block in the Green World (GW) construction area at the Expo site on 28 March 2024, including the cause of the incident, guidance from the relevant authorities, and measures to prevent a recurrence, was released on 19 April. However, it was discovered that there were some damaged areas that had not been reported by the constructor, and these were reported to the Japan Association for the 2025 World Exposition (hereinafter referred to as “the Association”) on 20 May.

After thorough measures were taken to prevent a recurrence, work involving the use of fire was resumed on 22 April. There is no change in the measures to prevent a recurrence as a result of this report, and we will continue to thoroughly implement these measures in the future.

1. Outline of the accident

On Thursday, 28 March 2024 at around 10:55, on the ground floor of the eastern toilet block next to the outdoor event square in the Green World (GW) construction area, sparks from welding work ignited methane gas that had accumulated in the piping pit, causing damage to the ground floor and other areas. No one was injured as a result of this accident.

Date and time of accident: Thursday, 28 March at around 10:55

Human Injury: None

Property Damage: Next to the event plaza in the GW construction area, on the first floor of the eastern toilet block.

・Damage to the concrete floor

・Damage to the floor inspection hole (Scale of damage: approximately 100m2) (New damage found in this report)

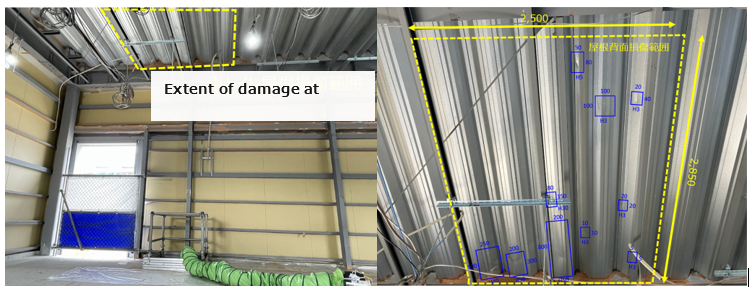

・Damage to the roof material (Extent of damage: 2,850 x 2,500mm, 10 dented areas)

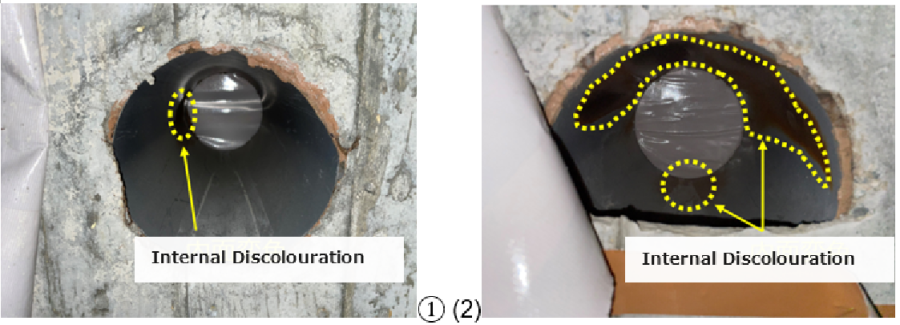

・Damage to the foundation beam sleeve (Damage: 2 areas, discolouration of inner sleeve surface)

* Sleeves are tubes that create holes for pipes and ducts to penetrate building beams, floors, and walls.

< Damaged areas of the concrete floor and floor inspection hole >

< Damaged area of roof material >

< Damaged area of foundation beam sleeve (underground pit) >

2. Cause of the accident

● Landfill gas generated from the soil, which is directly below the piping pit under the floor, entered and remained in the piping pit, resulting in high gas concentrations.

● In the piping pit, natural ventilation and mechanical ventilation were carried out and the gas concentration in the working area was confirmed to be less than the standard value before the work started. However, it is understood that the working area was on the ground floor and the inside of the piping pit was not an area subject to gas concentration measurement.

● Consequently, it is assumed that the direct cause of the gas explosion is that work using fire was carried out on the ground floor without measuring the gas concentration in the piping pit under the concrete floor, which led to sparks from the work igniting the gas.

3. Guidance and response from relevant authorities (Nishinoda Labor Standards Inspection Office and Konohana Fire Station)

● Between 28 March and 1 April, the relevant authorities conducted a site inspection. As a result, the fire station identified it as a fire (explosion fire).

● Following guidance from relevant authorities, the contractor has already submitted measures to prevent recurrence.

4. Measure to prevent recurrence

Following the accident, the cause was investigated by the constructor and a procedure for ensuring a safe working environment was reviewed as a measure to prevent recurrence. Gas concentrations are measured before all work is carried out, and work is only started when it is confirmed that the concentration is below the standard value. From now on, work will be carried out thoroughly according to this procedure manual. The procedure manual is outlined below:

(1) Thorough measurement of gas concentration before work

In addition to gas concentration measurements around landfill gas vents installed outdoors, as have been carried out in the past, when working indoors thorough measurement of gas concentrations in locations where there is a risk of gas retention (near the work floor and ceiling surface, in the ceiling space, and in underfloor piping pits) will be carried out.

(2) Measures to improve the environment during work

Piping pits under the floor should be kept open and natural ventilation should be provided at all times. If landfill gas concentrations above the applicable standard value* are found in the indoor work area and adjacent areas, mechanical ventilation using a blower or similar equipment should be carried out. After mechanical ventilation, the concentration will be re-measured and confirmed to be below the standard value before starting work.

* The standard value for methane, which was 30% LEL before the accident based on the Labor Safety and Health Regulations, will now be set at a more stringent 5% LEL for normal fire-use operations. The “%LEL” is a unit of measurement for the concentration of a target gas when its Lower Explosive Limit (LEL) is set at 100% LEL.

5. Opinions from experts on measures to prevent recurrence (procedures for ensuring a safe working environment), etc.

・There is no doubt that methane was the cause of this accident.

・Overall, the measures to prevent recurrence (procedures for ensuring a safe working environment) are adequate. If mechanical ventilation is used, there is no other possible countermeasure.

6. Future plans

・Work with fire resumed on 22 April, as measures to prevent recurrence have been submitted to the relevant authorities and procedures have been completed.

・In order to improve safety during the Expo, opinions of experts will be sought and measures implemented for buildings in the GW construction area (e.g. review of ventilation systems).

・Although the Pavilion World (PW) construction area is filled with construction debris, etc., no landfill gas has been detected in concentration measurements near the ground surface to date. With the possibility of landfill gas generation near the ground surface being considered extremely low, we will continue to measure gas concentrations in the Expo site, including the Pavilion World construction area.

[For Reference]

< Efforts to date >

1. Efforts at landfill sites

At the Yumeshima Area 1 disposal site, where Osaka Waste Management Authority carries out landfill disposal operations, gas venting facilities have been installed to treat the methane gas that is generated and to ensure that the methane gas does not accumulate in the landfill.

2. Design considerations for the construction of facilities in the GW construction area

When constructing the facilities in the GW construction area, measures are planned to be taken to prevent gas from entering the buildings.* A moisture-proof sheet will be laid under the foundation.

* Pipework for natural ventilation will be installed in buildings with underfloor piping pits.

3. Landfill gas measures to be taken by constructors in the construction of facilities in the GW construction area

Prior to the accident, the measures taken by constructors were as follows:

・Gas concentration measurements were carried out around the outdoor landfill gas vent installed as described above in (1).

・When working in a piping pit, the gas concentration in the area concerned was measured before the work was carried out in accordance with the Labor Safety and Health Regulations. The measurement standard was 30% LEL based on the Labor Safety and Health Regulations.

< Reference photographs of ventilation machinery >

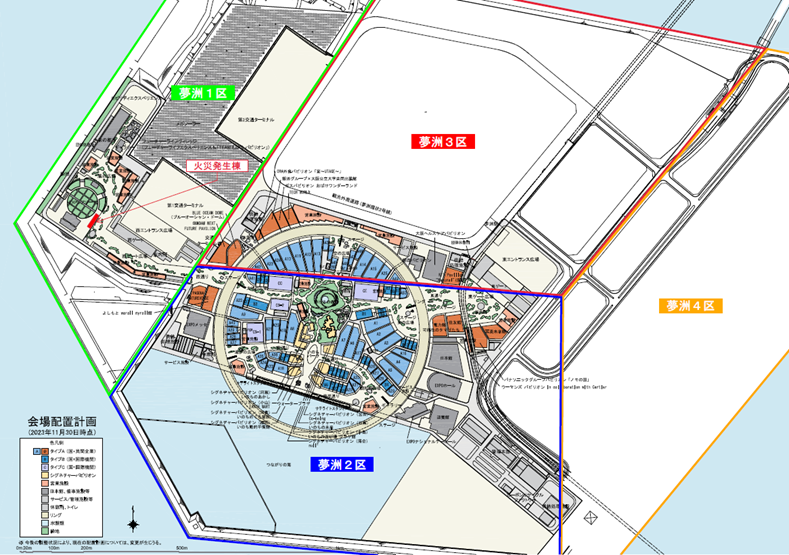

< Area map of Yumeshima Island Construction areas 1, 2 and 3 >