“There are three main ways out for old clothes to avoid being discarded as trash.”

Shuji Fujita, a director of “NAKANO,” which celebrates its 90th anniversary this year, talks about the challenges, “The first is for reuse, where items in good condition are sold again on the market. The second is for processing waste cloth into wiping/scrubbing cloth, a rag used to wipe off oil from machinery at factories and other places. The third is for recyclable materials that are once again converted back into cotton fibers and reproduced into interior finishing materials, etc. A fourth way out that can handle a certain level of volume is now required.”

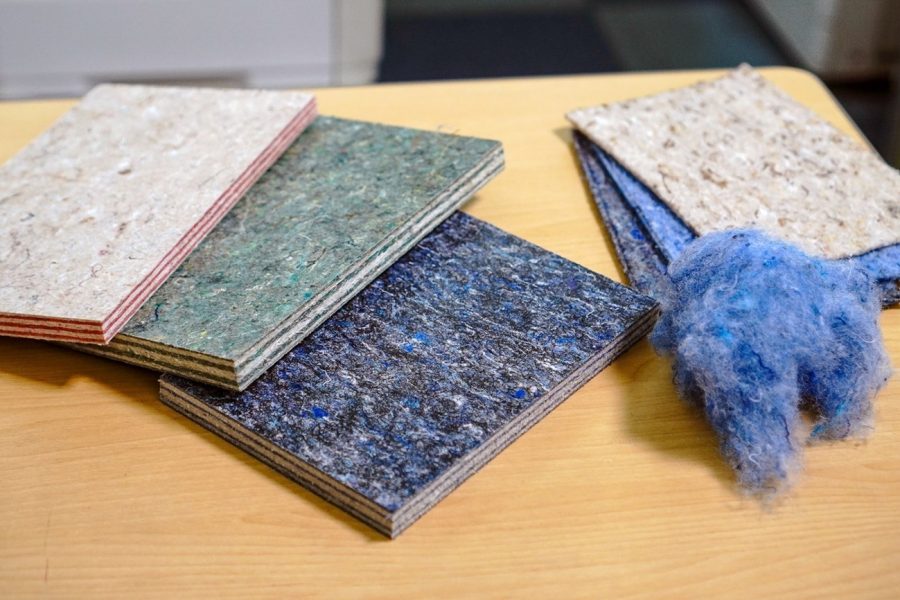

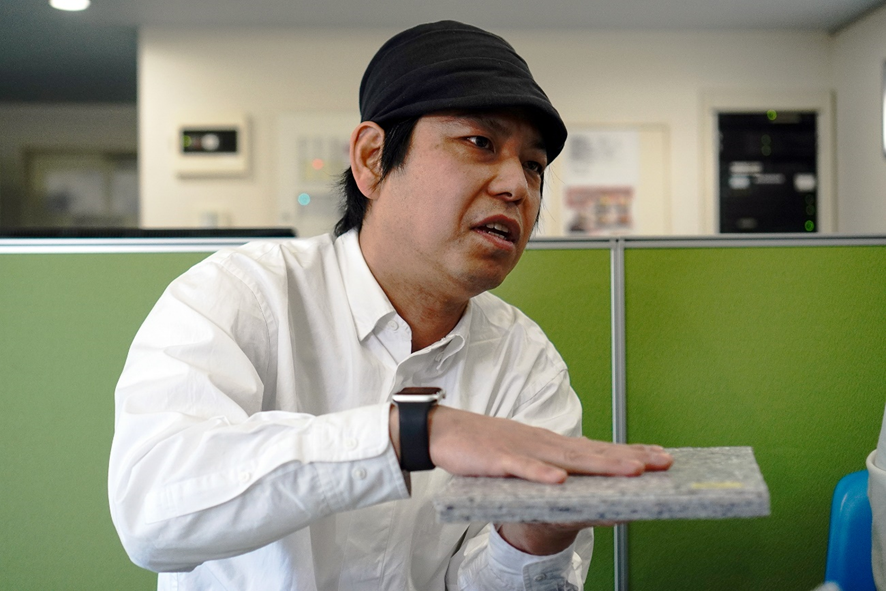

To enhance this “exit strategy,” under Professor Emeritus Kimura, Colourloop Co., Ltd., NAKANO & CO., LTD., and the furniture design company Abode Co., Ltd. teamed up for the challenging task of producing boards from various waste fibers. Abode has so far developed denim boards using resin mixed with discarded scraps from jeans production and “hard felt,” a new material made from recycled plastic bottle fibers. The company has an extensive track record, and last year, they partnered with Nippon Ham Fighters, a professional baseball team, to produce benches for a museum attached to a new stadium by mixing hard felt with discarded clothing, such as players’ uniforms.

On Uchimaru’s suggestion, he applied for the Co-Design Challenge, hoping that more people would be aware of the great challenge. The board would be commercialized as a bench and unveiled at the Expo site. Currently, they are in the process of modifying various conditions, such as the density of felt made from fibers by color, temperature and time for molding, and through a process of repeated trial and error, they are trying to determine how to achieve the right color and hardness.

“The items that should have been discarded can be recycled into new materials, thereby expanding the possibility of manufacturing. Nothing is more exciting than this. Besides, the waste fibers used as raw materials are different every time, so the same patterns and colors can never be seen again. It is truly once-in-a-lifetime experience. That is why there are infinite possibilities, and it gives us inspiration.” Abode’s president, Go Yoshida, was elated.

The Expo will provide an opportunity to showcase Japan’s recycling technology to the world. Fujita hopes that this will be a new business opportunity that will lead to the next market for discarded fibers. Uchimaru shares the same thoughts and states, “We have a cost issue and cannot compete with existing products in terms of price. However, we would like to create more and more up-cycled products that are attractive beyond their prices by enhancing their added value and that people would want to use without thinking. As a result, I would be happy if this resulted in a society where discarded clothing was reduced. That’s what we hope to show at the Expo.”

Share this article