The first model that came to mind was a household dishwasher with a bottle holder. However, it took about an hour to wash, which is too long under the assumption that the machine will be used on the go. They set a goal of reducing the time to about 20 seconds to make it easier for people to use.

In order to achieve speedy cleaning, they looked around for manufacturers that would provide them with technical assistance. After visiting the venues of exhibitions, they finally found a manufacturer called Nakano Manufacturing Co., Ltd. in Higashiosaka City, Osaka Prefecture. They expressed their passion for the “Personal Bottle Washer” and decided to utilize the company’s technology for parts washing machines. The problem, however, was that a parts washing machine was powered by high-pressure air. When commercialized, demand could be expected in corporate offices and cafes in the city. It would be difficult to install air compressors in such places, so the company had to redesign the specifications and components from scratch to make the machine electric-powered.

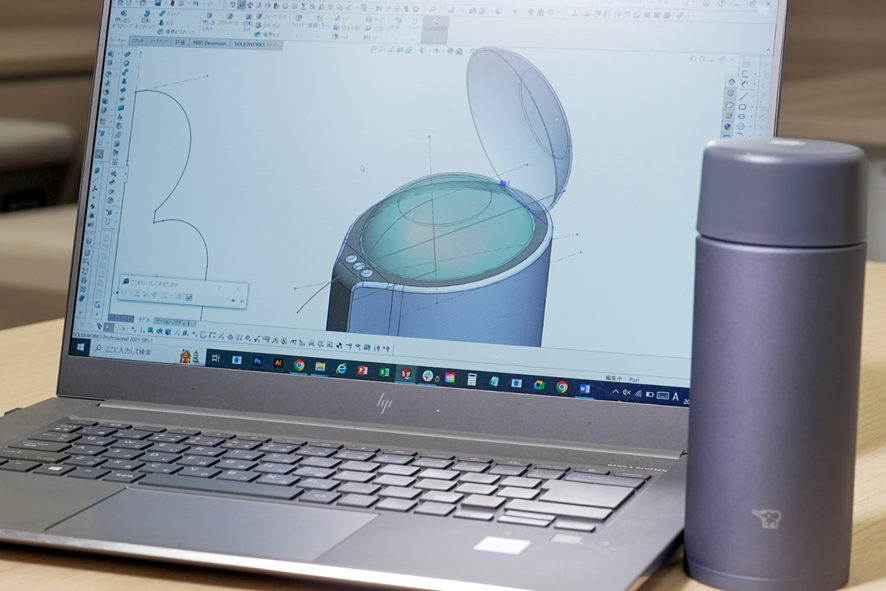

Other trials and errors continued. At first, the company had been moving forward under the assumption that the entire bottle would be washed, but because of the time and electric power required for drying, the company decided to limit the wash area to the drinking spout and inside of the bottle to achieve ease of use, speed, and energy conservation. Also, considering the impact on the marine environment and living creatures, they decided not to use synthetic detergents, but to use ozone water for sterilization. To prevent spilling over the surrounding floor due to malfunction, a sensor that reacts to the bottle was also installed.

It has been about four years since the concept was first conceived. While the basic specifications were being finalized, they learned about the Co-Design Challenge when they invited “STUFF” in Kadoma City, Osaka Prefecture, a company which provides a wide range of support for design, development, prototyping and mass production in order to further accelerate the development toward commercialization.

“As a company based in Osaka, we wanted to contribute in some way from the time when the prefectural government decided to conduct campaigns to host the Expo. We felt that the Co-Design Challenge was a great chance to collaborate as a solution brand,” said Iwamoto as he put his efforts into this project.

Solution brand development is an initiative by a company to enhance its value by aiming for solutions to social issues. It is also a major global trend. Zojirushi chose the “Personal Bottle Washer” as one of the tools to show the orientation of their solution brand.

In order to enjoy a personal bottle on the go, it is essential to expand beverage services for the contents of the bottle. Zojirushi has already partnered with cafes and Japanese tea stores to offer coffee, tea, and Japanese tea in a personal bottle at their shops nationwide. At the Expo site, Zojirushi plans to install washing machines next to the water dispensers and also collaborate with food and beverage booths.

Iwamoto envisions, “The Co-Design Challenge is a challenge for us, but I would like it to offer an opportunity for visitors to challenge themselves with new initiatives as well. By experiencing them, I want people to sense a future in which they can live comfortably without disposable plastics.”

Share this article