Colourloop Co., Ltd. is determined to add value to used clothing and old cloth, which used to be discarded, to be used in the market again and not to make a compromise about their designs. A project of expressing such passion with a bench and delivering it to the Expo site is progressing.

Based on the color recycling system established by Uchimaru of Colourloop, Nakano sorted used clothing and old cloth by color, and they conducted collaborative development involving three companies in different fields, including Abode, which possesses plentiful experiences of designing furniture. Consequently, they created TEXLAM, a board that can be used for crafting benches.

For producing TEXLAM, waste fibers are sorted by color and made into felt, and then several pieces of felt with different colors are laminated together. Yoshida of Abode said with confidence, “We tentatively produced over 30 kinds of boards to satisfy the requirements for producing a bench, including strength, density that ensures workability, and weight that ensures portability, and then succeeded in producing this board.” They plan to deliver five benches to the Expo site. To do so, they need to prepare around 50 boards of TEXLAM whose size is around 180 cm × around 90 cm, which is called “Saburoku-ban.”

In October 2024, the anticipated prototype of a bench was completed. Its structure is so simple that it can be assembled from TEXLAM without using any other parts or adhesives. The size of the prototype is one third of that of an actual bench, and its weight is around 26 kg. Assuming that a T-shirt weighs 100 g, the fibers of about 156 T-shirts are used for the prototype. For the five benches to be delivered to the Expo site, 2,350 T-shirts would be upcycled. They are planning to enlarge the seat, so the number of necessary T-shirts may increase. The curves of the net-like structure with two-colored layers exposed and its unique texture are eye-catching even from a distance. When the CG image was produced, Yoshida was worried about the steps after the bench is assembled, but the completed bench has dispelled such worry, and we can sit on it comfortably. They plan to provide blue and green benches to the venue. Seeing the prototype, Yoshida seemed satisfied, saying, “It looks good, and has a taste of craftwork.” Regarding “beautiful colors” pursued by Uchimaru, a deep blue has been realized.

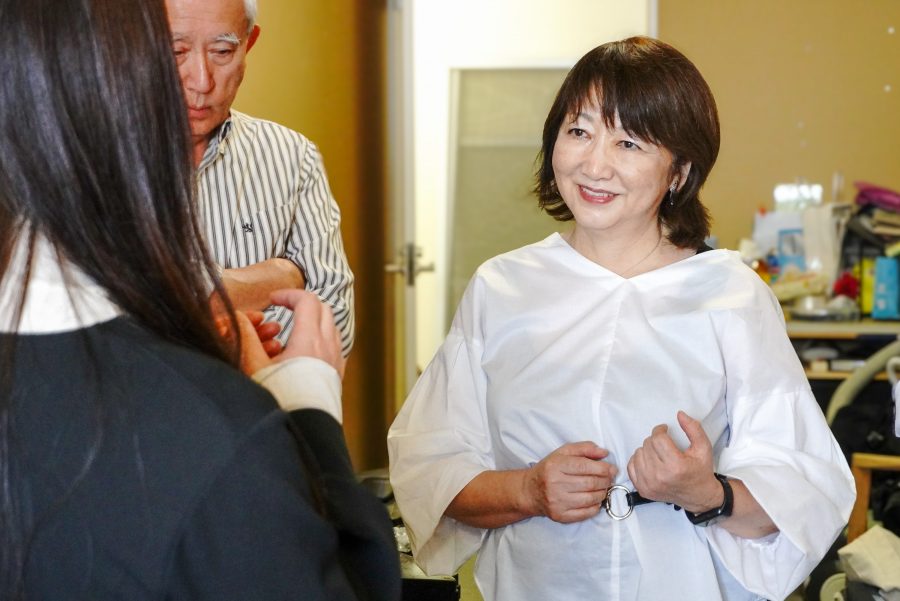

At the factory of Nakano, used clothing and old cloth are manually sorted by color based on the color chips designated by Uchimaru. Yoshida is reviewing the prototype and adjusting the depth of the bench, the entire contour, etc. Uchimura has endeavored to create a model for a recycling economy by using “colors” as a breakthrough. She insisted, “I hope to create products that look nice and fashionable rather than promoting customers to try them because they are recycled ones.” Uchimaru’s abilities to come up with ideas and take action attracted business partners sharing the same ambition, and her efforts are about to bear much fruit through the Co-Design Challenge.

Share this article