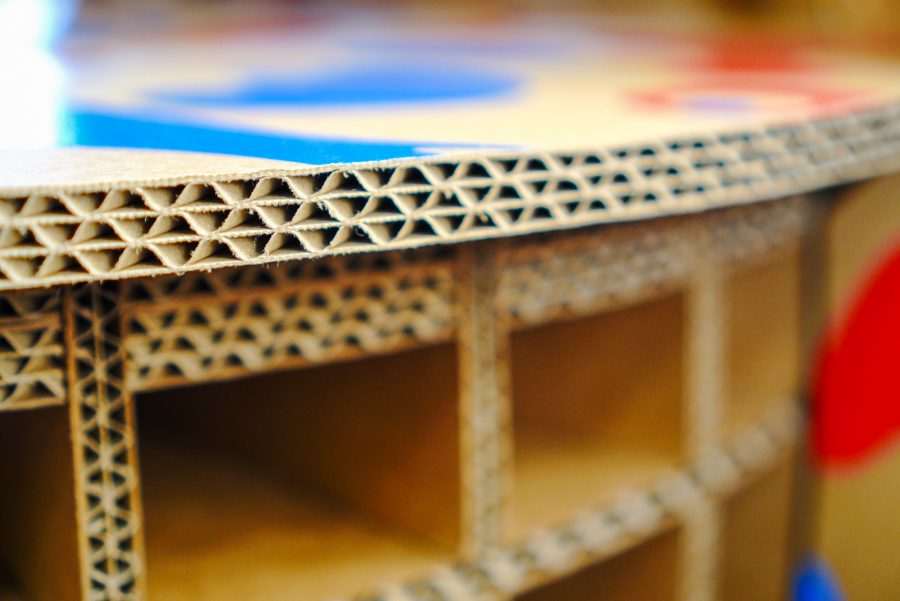

A semi-circular tower is wrapped around a round table to create an “enclosed space.” A prototype model of a nearly-2-m-high exhibition stand, assembled from 100 cardboard parts, was revealed. The cross section, deliberately exposed to show the presence of the cardboard, has a wavy pattern that gives it a sense of dynamism. Takagi’s pursuit of “new creation of cardboard boxes” has taken shape for the future.

14 exhibition stands will be placed in the “Future Life Village” in the “Future Life Zone” on the west side of the venue. Here, various entities, including small and medium-sized enterprises and educational institutions, will bring their proposals for future lifestyles for presentation, and this exhibition stand will be used for that purpose.

While making the most of its innovative design, detailed planning and a variety of ingenuity were used to ensure the strength and durability of the exhibition stand, which weighs a total of 25 kg. Weighing 9 kg, the 32-inch monitor was a challenge to install, but a stable balance was created by placing it in the center of the exhibition stand. The material used is made of two layers of reinforced cardboard (5 mm per layer) with wood-like hardness, and the round table’s top, where items are placed, is composed of three layers thick to withstand a load of up to 80 kg. They are assembled without any plastic or metal and can be recycled.

For Takagi Hoso, based in Katsuragi City, Nara Prefecture, cardboard is referred to as “DAN Board,” in which “D stands for Design,” “A for Affection” and “N for Natural.” Takagi, who took over business from her father as president in 2017, has continued to take on the challenge of differentiation, not only through cardboard manufacturing, which prioritises practicality, but also by focusing on design and increasing added value. The company has been working to create new value with a focus on “wrapping,” backed up by its high technological and production capabilities, which demonstrates “there is nothing that can’t be made.”

The experience-based event includes a tour of a manufacturing plant with about 10 machines that produce a wide variety of cardboard cases, including a fully automatic box-making machine that finishes 300 cardboard cases per minute, a high-definition printing machine and an automatic flatbed die-cutting machine. It is rare to find a factory where visitors can see a cardboard production line all at once, providing an opportunity to experience the excitement and the fun of making things.

Takagi Hoso, a company with around 100 employees, has a workforce where one-third are in their twenties. Takagi is leading the way toward realizing a “dream company” with a youthful and playful spirit. In 2025, the company will celebrate its 70th anniversary, and a new factory will be completed next year after the Expo. The exhibition stand used for the Expo will also be decorated, and there are plans to set up a “manufacturing learning booth” on the site as part of its contribution to the local community. The Expo will be a milestone year for the company. The potential of cardboard will turn this step into an even greater force for the future.

Share this article