There appeared a uniquely shaped bench with many curved surfaces as well as the beauty of the grain. It is “Connecting Contrails.” This design was adopted based on votes from pupils commuting to public elementary schools in Itami City, Hyogo Prefecture, which is involved with the project of Kokuyo utilizing local lumber. The four-layered cloud-shaped bench made of the lumber of roadside camphor trees that were cut down at the time of construction of a new government building will serve as a symbol of the connection between Itami, a town with an airport, and the world, and render the linkage of thoughts while envisioning the future of Itami. This project was initiated with the aim of embracing such ambition.

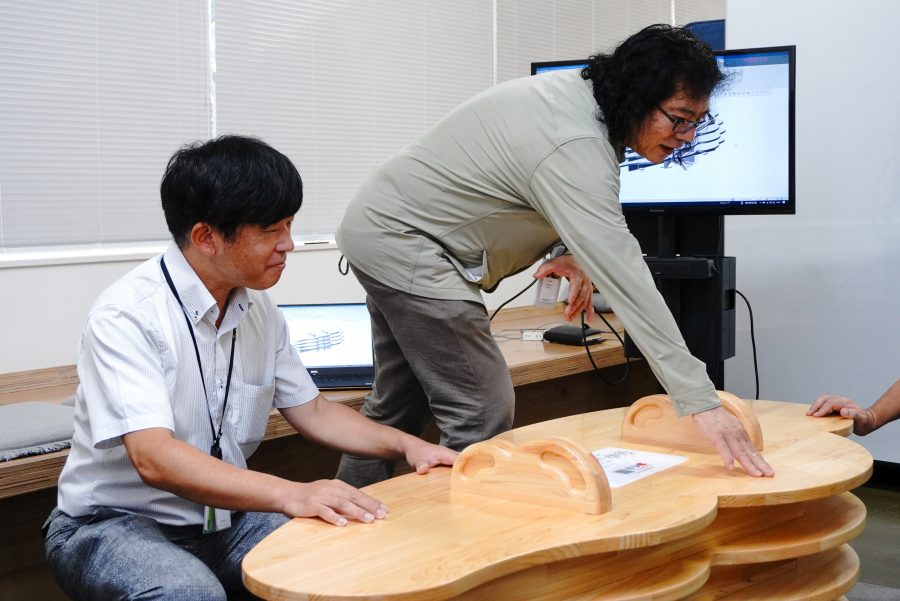

In order to produce “a wooden bench that can be used indoors and outdoors,” Kokuyo has no choice but to rack its brains and exercise its ingenuity because the company handles many office products made of steel. It was necessary to assume various things and conduct verification, just for choosing an adhesive for lumber. The salesperson Takamitsu Yamanouchi conveys requests to the in-house project team with the aim of creating a bench that matches the sustainable construction of a new government building while utilizing camphor wood. They pursue quality thoroughly without any compromise. Toshihiko Horita, who is in charge of procurement, faced many difficulties. The amount of camphor wood brought was 10 logs. Not all of them were usable, as there were some warps and knots. After sorting them out, they managed to secure 5 or 6 wooden boards with a size of 180 cm × 90 cm, and planned to use them for armrests or the components for supporting the first layer.

Before completion, there remains a round discolored part with a diameter of around 15 cm on the seat. This is a trace of the repeated drop impact test. Katsuhito Yui, who is in charge of product development, gives explanations. “According to the JIS standards, a 57-kg weight is dropped from a height of 36 cm 100,000 times, to test durability, etc., but this time, the test was conducted 100,000 more times, assuming non-Japanese people visiting Expo 2025 Osaka, Kansai, Japan.” No measures including those against ultraviolet rays or the care for safety can be disregarded. Yasuki Terao, who is in charge of design, carefully observed benches in a park he visited with his child, to seek some clues, and took pictures. “I hope that the bench will be used by kids forever.” Such father’s wish was also infused. In February of next year, they plan to assemble two out of six benches together with children at a workshop of Itami City. The team leader Hiroshi Sakai said, “Our task does not end when a bench is delivered. We consider how to maintain the bench. We came up with ideas from scratch, brought together the know-how of each section, and worked on this project with absolute confidence.” Kokuyo is proceeding with this kind of project utilizing local lumber in Shimanto Town, Kochi Prefecture and Kawachinagano City, Osaka. The endeavor for the future will become a great legacy for Kokuyo.

Share this article