Waste is an inevitable byproduct of the manufacturing process. While many companies are attempting to reuse the waste, Dots and Lines, which is located in Tsubame-Sanjo, Niigata Prefecture, is taking on the challenge of creating chairs with a production yield of 99% from a single board. Companies with top-notch technology have joined forces to take on the herculean challenge in an effort to pass it down to future generations.

Tsubame-Sanjo, which is the name of a station on the Joetsu Shinkansen Line, refers to the region in the middle of Niigata Prefecture that includes the cities of Tsubame and Sanjo. Tsubame-Sanjo is known as a manufacturing town, producing metalwork, cutlery, and Western tableware.

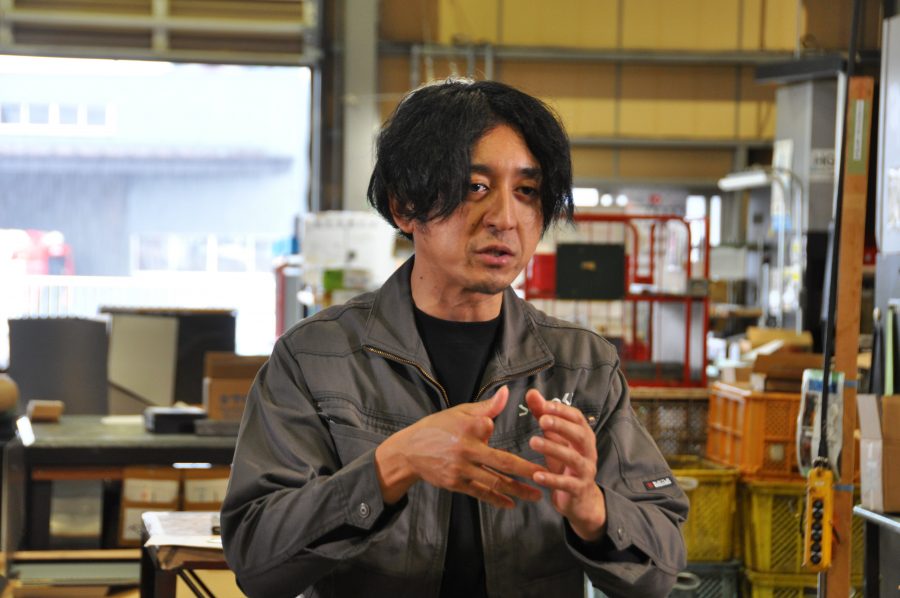

Dots and Lines was established in 2020, under the leadership of Kazuya Saito, who is engaged in the metal processing business in Tsubame-Sanjo. The company aims to contribute to manufacturing in ways that individual businesses cannot achieve by bringing together a diverse range of talent, including manufacturing craftsmen, designers, and planners, and combining their expertise and technology. “Dots” signifies “multiple points” and “Lines” signifies “multiple lines,” which expresses the company’s desire to connect each and every unknown technical skill, expertise, company, and person. As an initiative that embodies this, they have been operating the “JRE Local Hub Tsubame-Sanjo,” which is a workplace aimed at local revitalization, established in 2022 in Tsubame-Sanjo Station in cooperation with East Japan Railway Company. The “Tsubame-Sanjo Factory Information Center” set up within the workplace provides business matching services with companies that have fields of expertise.

Spearheading these efforts is Saito, who faced a major dilemmawhile working in the metal processing industry. While the shift toward a decarbonized society progresses, the heat source used to melt and solidify iron will unavoidably result in CO2 emissions. As a way to solve this with his own manufacturing, he thought, “Not only should we reuse the waste that is produced and turn it into another product, but ultimately it would be best not to even leave room for an opportunity for reuse. That is a shift in mindset from ‘not discarding waste’ to ‘not creating waste.’”

“I heard that at the 1970 World Expo, the black sun on the back of the Tower of the Sun was made of Shigaraki ware and became a local legacy. Given the emphasis on a recycling-oriented society, I wonder if we can offer products at the 2025 Expo that integrate Tsubame-Sanjo’s metal processing technologies based on the idea of ‘not creating waste’ in order to create an opportunity for a shift in mindset in all manufacturing-related fields. Instead of focusing on a particular product, we wish to communicate this concept. If we succeed in doing that, I think it will become a source of pride and hope for the children living in this area,” said Saito, explaining his thoughts on solving the problems he faces and his vision for the local community.

What kind of product should be made? And how can they avoid generating waste during its processing, or in the case of sheet metal stamping, any blanking material? Dots and Lines designer Akihiro Goto, drew inspiration from origami. “To avoid wastage, we can just use a single piece of board as it is, just like origami. By folding a single piece of board, we can create a chair.”

(Right) Designer Akihiro Goto; (Left) Representative Director Kazuya Saito

Share this article