Visitors are sure to be drawn in by the sophisticated design of the bicycle Hotamet that staff members will be wearing at the Expo site when they ride on a vehicle. With a smile, Nambara said, “We want to have a great time at the Expo and wish for a lot of people to witness the thriving manufacturing industries in Kansai and Japan.”

Some colors of the Hotamet are in such high demand on the company’s online store that production is unable to meet demand. One company placed a bulk order, saying, “We want to give these to our employees to raise awareness of road safety. Please arrange for them to arrive on their birthdays.” Although the helmet is only available in a one-size-fits-all version for adults, a number of customers have left comments inquiring as to whether the product comes in a children’s size or wishing to get a matching set for parents and kids because they are so fashionable. Due to the unexpected popularity, Nambara promptly started creating two new styles of bicycle helmets for children aged three to eight. They both feature the same design as the adult version, maintain strength and have air holes to keep them from being stuffy and hot in the summer. He said, “We hope to launch these helmets around May 2025, utilizing SHELLTEC’s technology, which combines strength and lightness.”

The company is additionally considering making more durable industrial helmets to shield workers’ heads in factories and construction sites. New products are being created with the idea of “protection.” Additionally, they are collaborating with a sake brewing company in Osaka Prefecture to host workshops while bringing modest production equipment to the Expo site. A project to process tens of thousands of tons of scallop shells for industrial usage is also in progress, in addition to these everyday necessities. The purposes of use of scallop shells are increasing.

Nambara now envisions the future. He believes that it will become a widespread practice to use upcycled plastics made from seashells in home appliances and automobile parts. Using seashells will reduce the amount of petroleum-based plastics used, which will lead to a reduction in the burden on the global environment.

“All of the synthetic products we create are actually made of materials taken from the natural and biological world. If you look at the components of waste, they are the same as those found in nature and the living world,” said Nambara. In the case of Hotamet, the component is calcium carbonate, which is found in seashells. It is of biological origin, as it is created when shellfishes such as scallops and oysters absorb carbon dioxide that has dissolved in seawater. “Our helmets are made of this material. Nature and the living world provide us with many wonderful blessings,” he said. He loves seafood, and whenever he visits seafood producing areas, he enjoys freshly caught scallops. While he is impressed by the deliciousness of seafood, he never forgets his respect for all living things.

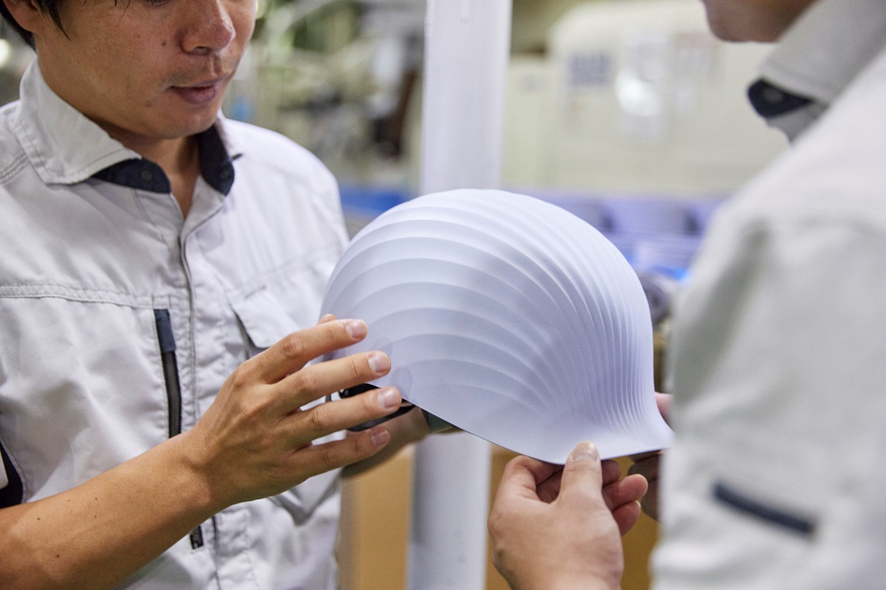

Mr. Tetsuya Nambara, Head of Planning and Development Department

Scene of a meeting with “Hotamet” in hand

Share this article