“This is no good. No matter what, the color is always coming out uneven.”

In late January 2025, the project was nearing its final stage. The final stage of coloring involves forming an extremely thin, transparent oxide film on the titanium surface to bring out vivid colors. At that point, Saito was faced with a decision. The color was slightly uneven in dents and welds that were barely visible to the naked eye, and none of the uncompromising craftsmen involved were satisfied with the finished product. With the delivery deadline looming, how far would they go to ensure perfection?

Considering the budget and the time remaining, he could have chosen to deliver the product as it was. However, Saito was very proud of the “polishing technique” of Tsubame-Sanjo, which has been developed since the Edo period through friendly competition and training by anonymous craftsmen. Steve Jobs was so impressed with Tsubame-Sanjo’s polishing technology that it was even used to polish the mirror surface on the back of Apple’s portable music player, the iPod. This has proved that Tsubame-Sanjo’s polishing technology is the topnotch in the world in both name and reality. “As long as it bears the name of Tsubame-Sanjo, we cannot present a half-baked product at the Expo, where people from all over the world will gather,” Saito determines. Not a single person opposed Saito’s decision to start polishing the base from scratch. Everyone felt the same way.

In early February, the surface of the chair was finally finished and polished to an extremely uniform and flat finish. The titanium itself had a beautiful black shine and a deep texture, as if it contained the determination of Saito and his team, who were putting the pride of Tsubame-Sanjo on the line. The reason why Saito and his team were so serious about taking on the Co-Design Challenge was because they were strongly attracted to the concept of “co-creation.” Not only the companies of Tsubame-Sanjo, but also the various regions participating in this special program are working together to raise the level of the manufacturing industry in Japan as a whole by combining their technological strengths to create a synergistic effect.

“To achieve this, I will become the ‘Pirate King’ of the manufacturing world originating from Tsubame-Sanjo,” Saito declares, quoting a catchphrase from the protagonist of a boys’ manga called “One Piece,” which is popular around the world for its unique worldview and epic storyline. Coincidentally, Saito was appointed as chairman of the Junior Chamber International (JCI) Tsubame-Sanjo in January of this year. “In the manga, the title of Pirate King is given to the person who is the freest in the world, who never gives up no matter how many times they hit the wall, and who, together with great friends, obtains the Greatest Treasure of All,” he says. Using the Co-Design Challenge as an opportunity, Saito will gather companions, expand the circle of solidarity beyond ties and existing frameworks, and take on the world. He dreams of an irreplaceable treasure for the Japanese manufacturing world that he will be able to seize at the end. The story of Saito and his companions has just begun.

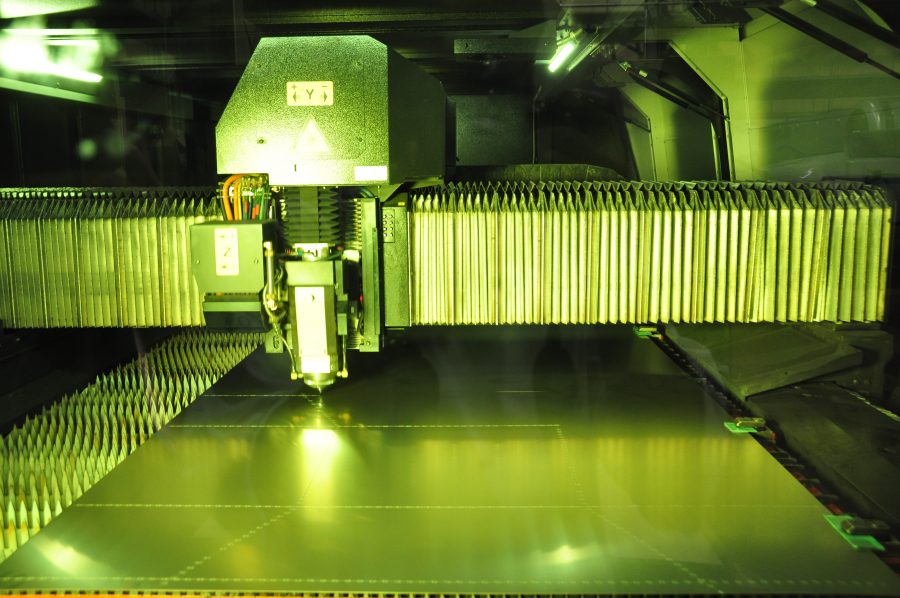

Creating fold lines on a titanium plate using laser processing

Folding a titanium plate into the shape of a chair like origami

Mr. Kazuya Saito, Representative Director of Dots and Lines Co., Ltd.

Share this article