Tetsuya Nambara, Head of Planning and Development Department of Koushi Chemical Industry Co., Ltd., a plastic processing company based in Osaka City, felt that the Expo 2025 Osaka, Kansai, Japan, which attracts attention from all over the world, would be great. It was when the company’s Hotabench, which is made from scallop shells that have nowhere to go, was officially adopted as one of the benches installed in the venue of the Expo 2025 through the Co-Design Challenge. What led to the birth of the bench was an enthusiastic public reaction to Hotamet, which was adopted as one of the official anti-disaster helmets of the Expo through another Co-Design Challenge.

While people in places in Hokkaido, such as Sarufutsu Village, which has been thriving on scallop fishing, had difficulty in disposing of shells, Nambara found value in shells and developed an upcycled product, Hotamet, on his own by making use of waste shells. He received a surprisingly large number of messages via social media right after it became official that his company’s Hotamet would be adopted as one of the helmets for the Expo 2025. He was flooded with inquiries, including the one asking where the helmet is available and the one that proposed to work together, from multitudinous organizations and companies based not only in Japan, but also in overseas countries, such as South Korea and the United States. One of them caught his eye, and it was a proposal from Shimizu Corporation (headquartered in Tokyo) to develop a new material by mixing scallop shells and cement.

In 2019, Nambara decided to change jobs and joined Koushi Chemical Industry, which was established by his grandfather and taken over by his father. He worked for a major general contractor after graduating from university and engaged in large-scale construction projects, such as construction of hotels and tunnels, through which he acquired in-depth knowledge of the construction industry. He knew that Shimizu Corporation, one of Koushi Chemical Industry’s competitors, has a cutting-edge and large-scale three-dimensional (3D) printing technology. Calcium carbonate, the principal ingredient of shells, goes well with concrete that is made by hardening the mixture of cement and sand. The use of the 3D printing technology for shaping a new material, in which shells are mixed, into products will open up greater possibilities of upcycling.

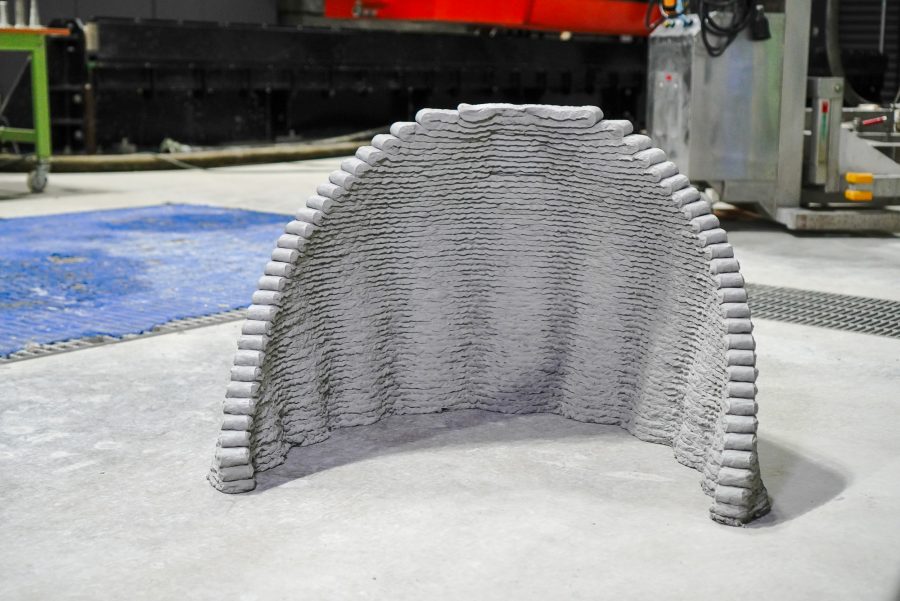

Nambara immediately got along very well with Tatsuya Ogawa, the engineer in charge of the 3D printing technology at Shimizu Corporation because both of them have put their heart and soul into manufacturing. They set a goal of developing a bench on which everyone can relax at the venue of the Expo 2025 and repeated experiments on proportions of shells to such matters as cement and sand and meetings regarding design in rapid succession. Nambara found great comfort in the production environment where they brought their respective strengths and discussed openly and honestly with each other. He felt that the project moved forward more speedily than any other projects and it was very exciting. They completed a prototype several months later. The prototype is a single-seater sofa with a height of about 50 cm. The design of the backrest, which is nearly semicircle in shape, was based on a gentle wave. According to Ogawa, the wavy design not only reminds people of a scallop, but also boosts the strength of the bench. Nambara said, “The shape of a shell that protects its soft inner parts from foreign enemies is rational. It has provided me with renewed feelings about how wonderful nature is.”

It was the moment when a “future design” made in Japan was born out of a combination of the technologies of the small factory and the leading general contractor.

Mr. Tetsuya Nambara, Head of Planning and Development Department of Koushi Chemical Industry Co., Ltd.

Mr. Tatsuya Ogawa from the Construction Technology Division of Shimizu Corporation

Share this article